The History of Rubber Rollers

Prior to the invention of rubber, humans utilized wood and metal rollers. Without the invention of vulcanization by Charles Goodyear in 1840, rubber rollers would not exist. Goodyear discovered that adding sulfur and lead to rubber and putting it in a stove made it weather resistant, chemical resistant, water resistant, and stretchy. As engineers experimented with the technique, manufacturers of the Industrial Revolution realized that by adding soft or hard rubber to a hard steel shaft, they could accomplish material nipping (pinching or squeezing) applications that steel alone couldn’t. As a result, the rubber roller was created.

Following the invention of the rubber roller, producers in a wide range of industries began to use it for their purposes. Publishers, for example, began using rubber rollers to spread thin adhesive layers and apply ink to their printing plates in the 1920s.

Little has changed about the rubber roller in the years since then, save for the rubber materials utilized in its manufacture and the purposes for which it is employed. Rubber rollers’ material and application options have expanded rapidly in recent years.

Industrial Rubber Rollers

Rubber rollers are utilized in a wide range of manufacturing processes for a variety of reasons. Rubber rollers are used in textile, film, sheet, paper, and coiled metal production processes. Rubber-covered rollers are found in a variety of container and package fabrication machines, as well as sanding and grinding machines for wood, steel, and aluminum.

Rubber rollers or rolls are utilized in industrial applications that demand a high level of contact and holding friction, as well as material processing applications that require a soft touch. Rollers are devices that roll or rotate and are often cylindrical or spherical in shape, such as a small spoke less wheel, a roller skate, or a caster. Printing also makes use of rollers. A firm rubber roller is used to ink the type before the paper is impressed for printing purposes. Rubber rollers are also perfect for roll-on decorating of large flat or curved surfaces, as well as peripheral

ornamentation of cylindrical shapes. In the graphic arts industry, covered rolls are often utilized.

Industrial rubber rollers are machine components that have a rubber-covered inner shaft. They’re usually cylindrical or spherical in shape to facilitate full rotation. Because of the tremendous adaptability of industrial rubber rollers and their capacity to be custom built to match almost any standard, it’s critical to engage with a rubber manufacturing firm and a rubber-covered roller supplier who knows your individual requirements.

Properties of Industrial Rubber Rollers

Vulcan s offers everything from little 1″ molded rubber rollers to giant 10′ wrapped rubber-coated rollers. Our competent technical staff manufactures the majority of roller shafts and other components in-house. Rubber rollers have a high-strength rubber-to-metal connection, are thermally efficient, and come in flat, stepped, or contoured shapes. Other industrial roller qualities include, but are not limited to:

- Resistance to heat

- Various hardness (durometers) to meet specifications

- Resistance to compression stress

- And more!

Custom Industrial Rubber-Coated Rollers for Any Application

Vulcans is a major manufacturer and supplier of rubber goods for any sector. We’ve had the honor of developing solutions for a variety of industrial applications, including:

- Marine

- Sporting

- Agriculture

- Plastics

- Conveyor Systems

- And much more!

Applications

Rubber rollers are commonly used for material application, movement facilitation, material support, and transportation.

Conveyor belt, assembly line, grocery store checkout line, mail machine, printing, rotary screen printing, automotive rubber components laminating, industrial heat treat equipment operation, automatic car wash movement, and boat trailer function are examples of these uses. They’re also frequently utilized as castors and wheels.

Rubber rolls, on the other hand, are generally used to assist move goods along with conveyor belts since the rubber has a high coefficient of friction, making it an ideal alternative for covering rollers.

Advantages of Rubber Rolls

Rubber rollers provide a wide range of benefits to their users. To begin with, rubber rolls, unlike metal rollers used in conveyor systems, have a high coefficient of friction, which gives excellent traction in moving parts and components. Rollers can also adjust for minor variations in machine functionality. Furthermore, these rollers provide all of the benefits of rubber.

Rubber is a common material for manufacturing rollers and aiding with item movement because it can be compressed and relaxed repeatedly without losing its form. A material that couldn’t keep its form and had to be replaced on a regular basis would be practically unusable. Rubber can also cushion shocks while also resisting and protecting against damage and scratching. Rubber rollers are the most cost-effective option, providing increased roller lifetime as well as physical and emotional benefits such as:

- Surface with a high coefficient of friction

Under clean and dry circumstances, the coefficient of friction between steel surfaces is between 0.5 and 0.8. A similar result of 0.45 is obtained when aluminum as compared to steel. Rubber, on the other hand, has a coefficient of friction ranging from 0.6 to 1.2 for diverse materials, making it an ideal lining material for transporting very sensitive manufacturing processes such as coated and laminated goods. When transporting objects on a non-level plane, a high coefficient of friction can propel material and/or prevent items from sliding.

- No burrs from scratches and tears:

Harder materials are easily scraped by metals. These scratches can cause burrs on the roller’s surface, which can harm items while in use. The rubber coating on rollers protects the metal core from being damaged. In comparison to the sharp burrs from a scratched metal, any damage to the surface of the rubber is not as damaging to operation

- Resists deformation from impacts:

Different varieties of rubber may survive different chemical exposures. It can prevent corrosion to the metal substrate, which can cause irreversible damage to the roller, by completely coating the roller core. Stainless steel, which is significantly more costly than rubber linings, is the most preferred alternative for a metal roller to withstand chemical assaults.

- Better chemical resistance:

Harder materials are easily scraped by metals. These scratches can cause burrs on the roller’s surface, which can harm items while in use. The rubber coating on rollers protects the metal core from being damaged. In comparison to the sharp burrs from a scratched metal, any damage to the surface of the rubber is not as damaging to operation.

- Replaceable:

Different varieties of rubber may survive different chemical exposures. It can prevent corrosion to the metal substrate, which can cause irreversible damage to the roller, by completely coating the roller core. Stainless steel, which is significantly more costly than rubber linings, is the most preferred alternative for a metal roller to withstand chemical assaults.

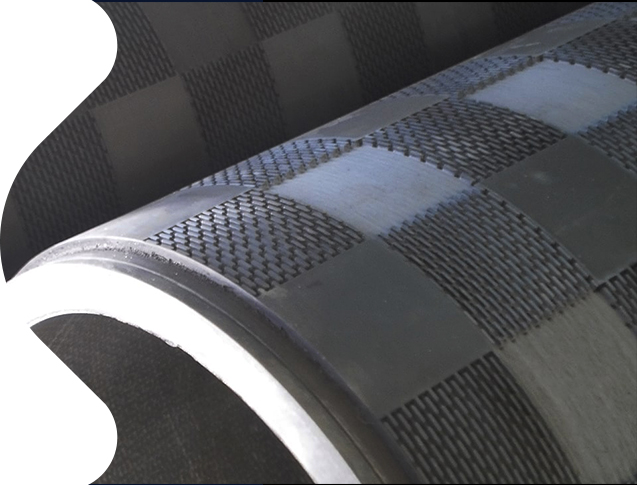

vulcanized rubber rollers

Vulcanized rollers are typically tiny, with diameters ranging from a few millimeters to 100 millimeters and lengths ranging from 20 millimeters to 580 millimeters.

Furthermore, following the molding step, bespoke forms such as rhombuses, across lines, and infinite screws can be engraved on the surface.

Its use ranges from dropping dust or liquid into wood, glass, or marble machines to handling plastic bags, vials, and syringes…

Customers can pick from a variety of personalization options.

Dimensions

Vulcanized rollers are typically tiny, with diameters ranging from a few millimeters to 100 millimeters and lengths ranging from 20 millimeters to 580 millimeters.

Materials

Different materials, such as brass, aluminum, and iron, are used to make rollers.

Depending on the roller application, they can be coated with any rubber type available on the market.

Special processing

Rollers can be formed using a specific grinding stone and special equipment, like in the case of polyurethane rollers used in packing machines to increase film grip.

Applications

Panel handling, paper and film dragging, and woodworking machines all use our vulcanized rollers.

roll covering material

Manufacturers have a wide range of elastomeric materials to select from. Each material has its unique set of advantages and disadvantages, but they all have some amount of resistance to water, wear, chemicals, and temperature extremes.

EPDM, silicone, nitrile, neoprene, polyurethane, and natural rubber are just a handful of the materials commonly utilized to make rubber rollers. Metal core rollers are often constructed of steel, stainless steel, aluminum, or another metal that meets the criteria of the application.

Rubber roller

Rubber rollers are utilized in a wide range of manufacturing processes for a variety of reasons. Rubber rollers are used in textile, film, sheet, paper, and coiled metal production processes. Rubber-covered rollers are found in a variety of container and package fabrication machines, as well as sanding and grinding machines for wood, steel, and aluminum. A rubber roller is a machine part made out of an inner round shaft or tube that is coated in elastomer compounds on the outside. Steel, aluminum alloys, or other strong and stiff material composites make up the inner shaft. The outer layer is usually made of a polymer like polyurethane, silicone, EPDM, neoprene, or natural rubber. Rubber rollers are used in a variety of manufacturing processes to fulfill tasks like:

- Printing

- Pushing and Pulling

- Film Processing

- Material Conveying

- Squeezing and Wringing

- Straightening

- Cooling and Uncooling

- Pressing

- Laminating

- Driving

- Deflecting

- Feeding

- Spreading

- Coating

- Grains Milling

- Pushing & pulling

- Wringing

- Straightening

- Coiling/Uncoiling

- Driving

Rubber Roller Construction

The roller core and the rubber cover are the two major components of a rubber roller. The key structural component related to the process system is the roller core. In contrast, the rubber cover is the component that comes into touch with the load. These sections are expanded upon further below.

Roller Core:

The load is supported by the roller core, which is a rigid structural element. High-strength materials such as carbon steel, stainless steel, alloy tool steel, and aluminum alloys are commonly used. Roller cores are made to fit certain purposes. They can be further subdivided into various sections. Cores can be as basic as a tube with bearings fitted on either end fixed on a shaft, or as complex as a completely formed body with welded end plates and shaft (or journal). Bearings can be installed on either journal end to enable free rotation, or a long shaft with a key can be used to drive the roller by the process. This can be further divided into various sections.

Shaft

The shaft is the component of the machine that links the whole roller to the motor, sprocket, or other drive units. Its structure is generally solid, with great strength and homogeneous hardness. The shaft is made to withstand bending and torsional forces.

Radial pressures on the roller create bending stresses, whereas torque generated by spinning the roller to tangentially shift loads causes torsional stresses. The shaft can be connected to the drive unit using a key and keyway, set screws, or machined flats, or the bearings can be installed in a housing or pillow block fixture in the case of a free spinning roller.

Cylinder:

A cylinder is a hollow element that is usually shaped like a pipe or tube. The rubber liner is wrapped and glued in this area. The metal is thick enough to prevent deflection when a load is applied. Steel is the most common material for the cylinder, however other stiff yet light materials such as aluminum and reinforced polymers can also be utilized. The cylinder’s ends are usually machined to accept pressure from bearings or a metal flange (end plate).

Flange:

The cylinder is connected to the shaft via the flange or end plate. Welds hold the shaft, cylinder, and flange together.

Bearings:

Bearings are used to minimize friction between rotating and static components. Depending on the roller’s design, the bearing’s arrangement, installation, and type may differ. The shaft and roller cylinder are placed together in the preceding arrangement. Other configurations allow the bearing to be put on the roller while the shaft on the main equipment remains stationary.

Manufacturing Process

The fabrication of the roller core, rubber compounding, bonding, covering, vulcanizing, grinding, and balancing are all steps in the manufacture of a rubber roller. Other fabrication companies can provide the roller core, or the rubber roller maker can make it in-house.

Roller Core Fabrication and Preparation:

Sheet rolling and welding are used to create the cylinder or hollow tube. This might be done by the rubber roller producer or a separate steel tube manufacturing facility. This tube’s ends can be machined to accept bearings. Flanges or support discs that are sized to fit within the cylinder are cut if necessary. A shaft is made by turning a metal stock into a cylindrical core in a lathe machine. This shaft can be welded to the flanges or slipped into the bearings on each end of the tube, as described above. To achieve the desired diameter, roundness, and balancing of the roller, all parameters must be precise. The flanges are then welded to the cylinder’s ends, together with the shaft. The roller core is exposed to secondary operations such as blasting and cleaning after manufacture to eliminate any traces of corrosion or impurities from its surface.

Rubber Compounding:

Rubber compounding is the process of adding chemicals to raw rubber to change its ultimate mechanical and chemical qualities, reduce its cost, and improve its processability and vulcanization. The rubber’s polymer chain is broken down by heating and masticating, making it responsive to the compounding chemicals. Roll mills, banbury mixers, and screw kneaders are used (extruders). Filler systems (carbon black, silica, calcium carbonate), plasticizers (for softening and processing), stabilizer systems (antioxidants, antiozonants), and vulcanizing agents are all common compounded constituents (sulfur, peroxide).

Bonding and Building:

The process of gluing the rubber cover to the surface of the roller core is known as bonding. It’s usually done with a heat-activated chemical bonding agent, however an ebonite base layer is occasionally employed. The rubber-building process can begin when the bonding components have been applied. Rubber building is the process of using a rubber compound to cover or line the stiff roller core. The following are some of the most common rubber-building techniques.

Plying:

Plying is the most typical process, which includes feeding calendered rubber sheets or strips while rotating the roller core. The rubber sheets are wound or wrapped around the roller until it reaches the desired diameter. To give some pressure to securely wrap the rubber cover, the roller core can be pushed against two or three rollers.

- Extrusion:Instead of employing calendered rubber strips, an extrusion machine’s rubber is glued to the surface of a revolving roller core in this procedure. Large rollers, such as those used in large paper mills, are better suited to this procedure.

- Casting or Molding:This procedure entails inserting the roller core into a mold or die and transferring or injecting rubber resin. To cure the rubber, the resin covers the roller core and is exposed to intense heat.

- Crowning: Crowning is a procedure in which the roller is shaped to have varied diameters throughout its length. When pressed against a load, this results in a tapered, convex, or concave form that allows for a small deflection. Crowning compensates for any roller core deflection caused by a severe process load. The processing strip is likewise kept in the center of the roller by crowning.

- Groove Cutting: Groove cutting is the process of creating depressed and elevated regions on the roller’s surface to enhance the roller’s surface area, decrease slippage, promote heat dissipation, and apply embossings and print patterns.

- Grinding:The rubber surface might have a circumferential or angled groove(s) ground into it. Grooving is used for numerous purposes, including tracking, spreading, grasping, mechanical clearing, surface contact reduction, fluid evacuation, and heat dissipation.

- Specialty Surface Finishes: The rubber covering may be machined to provide a variety of surface finishes. To aid avoid slipping, textured and crepe (or abrasive) surfaces might be provided. In operations where there can’t be any grind or scratch marks on the result, high polished surfaces are employed. A repeating pattern can be embossed on a surface, which is frequently done with a laser.

- Roller Core Balancing: There are two ways for a roller core to become imbalanced: static and dynamic imbalance. When a roller is allowed to rotate freely, it will roll to its heavier side, which is known as static imbalance. A dynamic imbalance, on the other hand, occurs when the roller is rotated to its working speed and produces a rocking motion or vibration. Dynamic imbalance is usually checked and adjusted using rubber rollers. Testing the roller in a computer-controlled dynamic balancing system at its usual working speed is how dynamic balancing is done. The position and quantity of counterbalance required are then determined.

It’s all about the service.

Vulcan Sanat Sepahan Company (also known as VSS Co.) was created in 1992 as a specialist, fully integrated international manufacturing group with a core specialization in rubber manufacturing. This company specializes in different forms of rubber. It focuses on designing and manufacturing in mines, tiles, textiles, port and shipping, rail and wagon, packaging and publishing, steel and vehicle manufacturing with a dependable enterprise. Because of the long experience and background, the experts at this company can provide appropriate solutions in the fields of ultra-heavy rubber products, ball mill liners, various compounds, rubber and wheel coverings, metal molding, and complex element designs. The company’s customer service staff has been able to understand customers’ needs and wants, allowing the company to satisfy the needs of national industries for rubber parts as well as modernize and use laboratory equipment in the field of quality production and employment.